Our Services

Production Wire EDM

We consistently produce high-value parts for demanding industrial applications

Learn More

Our Services

Water Jet Cutting

We offer water jet cutting services for the production of parts from prototype to high volume

Learn More

Our Services

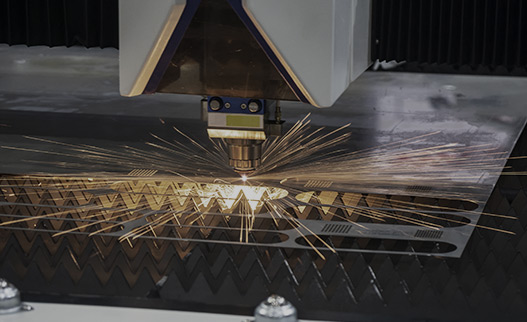

Fiber Laser Cutting

We can cut through an extensive selection of materials from thin metals to heavy plate, with a high degree of accuracy and repeatability

Learn More

Our Services

CNC Machining

We offer CNC machining services for the production of close tolerance metal parts

Learn More

Our Services

Small Hole EDM

As EDM specialists, small hole EDM drilling is one of our strengths

Learn More

Our Services

Laser Marking & Engraving

We leverage our laser marking and engraving system to add permanent information that identifies an item for total lifecycle traceability

Learn MoreMedical Devices

We have had the privilege of working with a wide variety of devices and implants since the inception of the company in 1985.

Firearm Components

Aerospace & Defense

Our company is AS9100-certified—an aerospace standard based on ISO 9001 certification, which demonstrates our adherence to stringent quality system requirements.

General Industry

About South Shore Manufacturing

At South Shore Manufacturing, we have 15 Wire EDM machines at our 10,000 sq. ft. facility in Hanson, Massachusetts. We proudly continue to provide our clients & partners with the Precision Machining Services & On-Time Results that they have always trusted and depended on.

Certifications

We are proud to hold a number of certifications to ensure the highest standard of production. These certifications include AS9100D, ISO 9001:2015, and ISO 13485:2016. We are also a Federal Firearms Licensed machining company.

Learn More Contact Us